Digital Management System

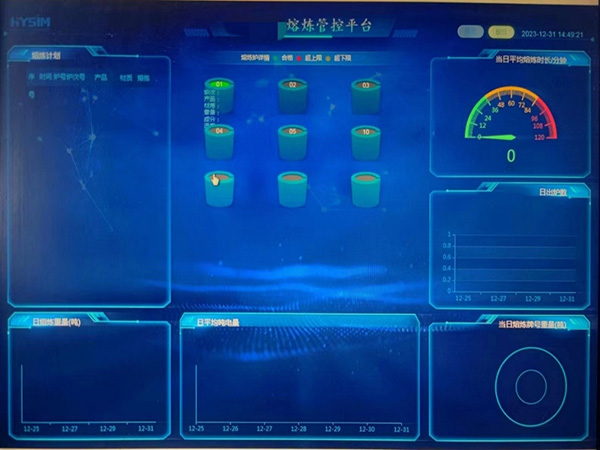

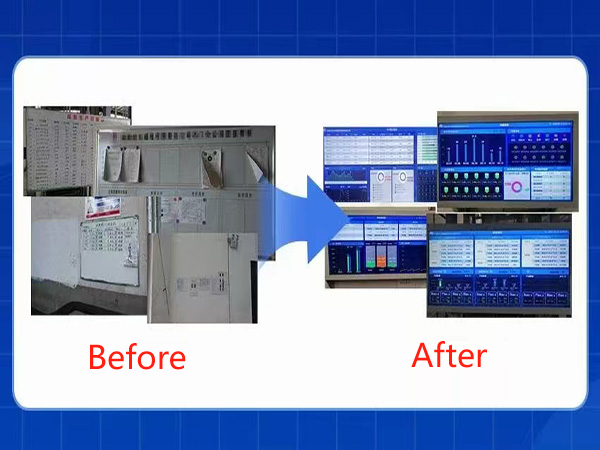

Recently, Dandong Fuding Engineering Machinery Co.,Ltd. officially introduced the latest digital smelting management system, which marks an important step forward in our journey towards smart manufacturing and digital transformation.

The digital smelting management system accurately manages key parameters in the smelting process through real-time monitoring and data analysis, thereby improving production efficiency, ensuring product quality and reducing operating costs.

How it work?

Real-time monitoring and data collection: Through sensors and data collection equipment, key parameters such as temperature, pressure, and composition during the smelting process are monitored in real time to ensure the accuracy and timeliness of the data.

Big data analysis and prediction: Using big data analysis technology, historical data is deeply mined to discover potential patterns and problems, and predictions are made through machine learning algorithms to optimize the smelting process.

Intelligent control and optimization: According to the analysis results, the smelting parameters are automatically adjusted to achieve intelligent control and maximize production efficiency and product quality.

Quality traceability and management: Establish a complete quality traceability system, and every link from raw materials to finished products is documented to ensure product traceability and qualified rate.

What are the advantages?

Improve production efficiency: The digital management system can monitor various parameters in the smelting process in real time, discover and solve problems in time, reduce downtime and failure rate, and improve production efficiency.

Ensure product quality: Through precise control and optimization of the smelting process, the system can ensure the quality consistency and stability of each batch of products and meet the high standards of customers.

Reduce operating costs: The automated and intelligent management mode not only reduces labor costs, but also significantly reduces production costs by optimizing energy use and reducing raw material waste.

Achieve green manufacturing: The digital smelting management system can achieve green manufacturing by optimizing energy use and reducing emissions, which meets the requirements of sustainable development.

Through the continuous advancement of digitalization and intelligence, we believe that the machinery manufacturing industry will usher in a brighter future. We look forward to working with more peers and partners to jointly promote the development and progress of the industry and realize the beautiful vision of mutual benefit and win-win.