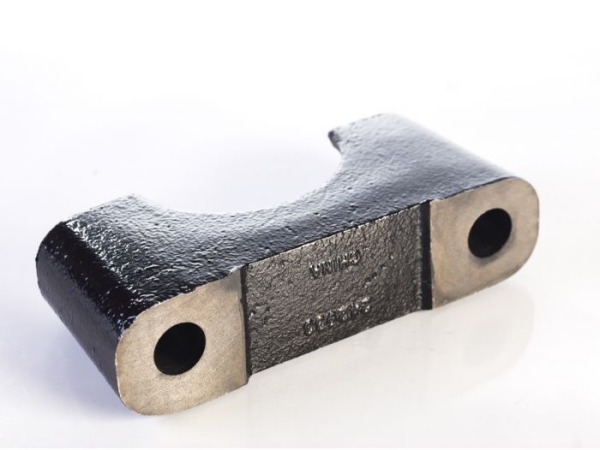

Advantages and disadvantages of cast iron bearings

The advantages of the cast iron bearing are: the cast iron bearing is wear resistant and does not hold the shaft when subjected to thermal expansion. It has simple structure, easy manufacturing, long service life and low cost.

The disadvantage of cast iron bearing is that if the hardness of the vibrating shaft is not high, the vibrating shaft is easy to wear after long-term operation.

Cast iron bearing materials are widely used in occasions where requirements are not too strict. The hardness of journal must be higher than that of bearing bush. The working surface shall be carefully run in with mixed resin of graphite and oil. It is required that the journal and bearing must be well aligned.

Is the bearing made of high manganese steel?

The needle of needle bearing is not manganese steel, but bearing steel. The needles of domestic needle bearing are generally made of GCr15 bearing steel conforming to GB/T18254, with hardness of 61~65HRC.

GCr15 (i.e. 52100) high carbon chromium bearing steel. It is a special bearing steel after electroslag remelting treatment, with high base purity, high density, uniform carbonization, fatigue resistance and wide application. For large bearings or large section bearings, heavy metals such as manganese or molybdenum will also be added to improve the hardenability and rigidity.

Can bearing steel be used as knife? How hard is it?

Yes, the hardness is about HRC58-61.

Bearing steel is different from other steels in processing and forging, so its characteristics are also different. First, it has high hardness, uniform distribution and can be used for a long time. Second, it has good wear resistance and can be used for machining. Third, the purity of impurities inside the steel is strictly required. If it fails to meet the requirements, it will be regarded as bearing steel. Fourth, it has good elasticity and good extensibility. It is precisely because of the strict production and high hardness of bearing steel that bearing steel is often used to make knives. How about the effect of making knives with bearing steel? The end edge is not sharp. First, bearing steel can be used to make knives. First, keep the bearing steel heating knife at 800 ℃ for about 3 hours, and then keep it at 700 ℃ for 2 hours, and then drop it to 500 ℃ before discharging. Tempering temperature should be lower, and more than 200 ℃ is appropriate.

Practical application of tapered roller bearings?

Tapered roller bearings can bear both radial and axial loads, and double row tapered roller bearings can bear bidirectional axial loads. Main applicable cages: steel plate pressing cage, synthetic resin shaped cage, pin type cage.

Main application: automobile: front wheel, rear wheel, transmission, differential pinion shaft. Machine tool spindle, construction machinery, large agricultural machinery, railway vehicle gear reducer, steel rolling mill roll neck and reducer.