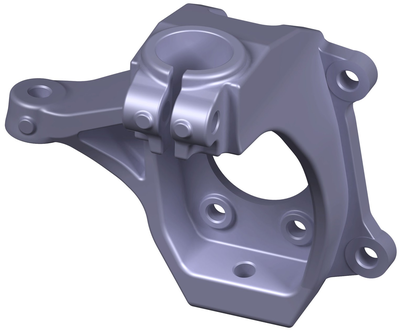

Casting of Automobile Steering Knuckle

The steering knuckle is one of the important parts of the automobile steering axle, which can make the automobile drive stably and transmit the driving direction sensitively. The function of the automobile knuckle is to transmit and bear the front load of the automobile, cast the knuckle, support and drive the front wheel to rotate around the kingpin to make the automobile turn. Under the driving state of the vehicle, the steering knuckle is subject to variable impact loads, so it is required to have high strength.

At present, the steering knuckle is cast with ductile iron as the main raw material, and carbon, silicon and other elements are added to form small carbon or silicon particles between iron atoms in the microstructure to strengthen the ductility (toughness) of alloy steel, and improve the tensile strength and fatigue strength of parts in the macro. Moreover, the content of carbon and silicon is required to be appropriate. Too much will make the alloy brittle and cause the strength to drop.

The automobile steering knuckle is a component connecting the automobile steering wheel and the front wheel axle, and is connected with the shock absorber. It mainly has three functions: (1) it is connected with the front wheel axle to bear the force and torque transmitted from the axle, (2) it is the rotating part of the vehicle steering, and (3) it absorbs the vibration of the vehicle in the process of moving. It is the most concentrated and complex part in the automobile, which is directly related to the safety performance of the automobile. Therefore, its design standards are very strict, and the manufacturing process and product testing are required to conform to the specifications.