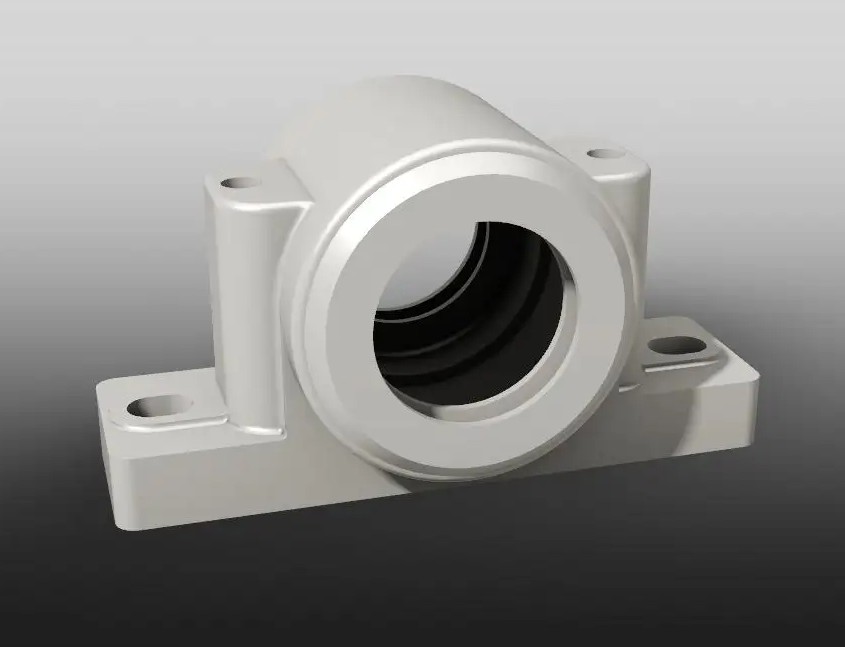

Common bearing housings have many advantages

There are two important types of sliding bearing equipment:

One is profile sliding bearing equipment, and the other is integral sliding bearing equipment.

1. Flush and check the bearing pads;

First, check the bearing model, clean the bearing, knock the bearing shell with a copper hammer, and check the cracks, holes and sand holes by listening statically.

2. Fix the bearing pedestal;

Make sure that the centerline of the bearing pedestal is on the same shaft. Then check the pulling method and painting.

3. Equip bearing shells

The key points to pay attention to when equipping bearing shells are:

(1) The contact surface of high and low bearing pads shall be tight

(2) Joint venture of bearing bush and bearing seat - common small interference joint;

(3) The bearing bush diameter shall not be too large or too small;

(4) The locating pin shall be firmly equipped;

(5) There should be no axial clearance between the flanging or seam and the bearing seat;

No matter how good the bearing block steel is, their use is limited, just like temperature. Under the service condition of the bearing seat, assuming that the mold temperature is too high, the mold core appearance is easy to crack in the early stage, and the one-sided bearing seat cracks in a large area, not more than 2000 mold times. Therefore, because the temperature of the bearing seat is too high, the die core changes color when the bearing seat is consumed.

Through measurement, it reaches above 400 degrees. At this temperature, the release agent is easy to crack in cold conditions, and the expensive products are easy to deform, strain and stick to the mold. When cold water is used for bearing block, the use of mold release agent can be greatly reduced, so that operators will not use mold release agent to lower the temperature of bearing block.

Its advantages are to extend the service life of the bearing seat, save the die casting cycle, improve the production quality, reduce die adhesion and strain, and reduce the use of release agent. It can also reduce the overheating of the bearing pedestal into the loss of ejector rod and core.

SNL large bearing pedestal adopts split planning: the main advantage of split planning bearing pedestal is convenient equipment; Pre assembled shafts can be equipped internally. After the base of the bearing seat continues to the support seat, just put the top cover of the bearing seat in place and tighten the connecting bolts to end the equipment.

The split type bearing housings that have been sold in the market are mainly applicable to self-aligning ball bearings, spherical roller bearings and CARB circular roller bearings. These housings are suitable for 02, 03, 22, 23, 30, 31, 32, 39, 40 and 41 ISO size series bearings. They can usually be fitted with a variety of seals. The split bearing pedestal has a variety of plans and variants, and does not need to apply a customized bearing pedestal, thus making bearing integration cost-effective.

SNL large bearing pedestals mainly include SNL30, SNL31 and SNL32 series 2. SNL large bearing pedestals use vertical planning vertical bearing pedestals with more advantages. SNL bearing pedestals of 30, 31 and 32 series are also called "large SNL bearing pedestals"

These housings enable the bearing to achieve a long service life while reducing the need for protection. This helps end users further reduce protection costs. In other aspects of enhancing efficiency, the planning of SNL bearing pedestal makes it easy to align and operate during the equipment process. Another advantage is that oil lubrication or grease lubrication can be selected for bearings fitted in SNL bearing housings. Thanks to the supply of a series of seals suitable for oil lubrication and harsh conditions, trouble free operation can be achieved.