Definition of casting

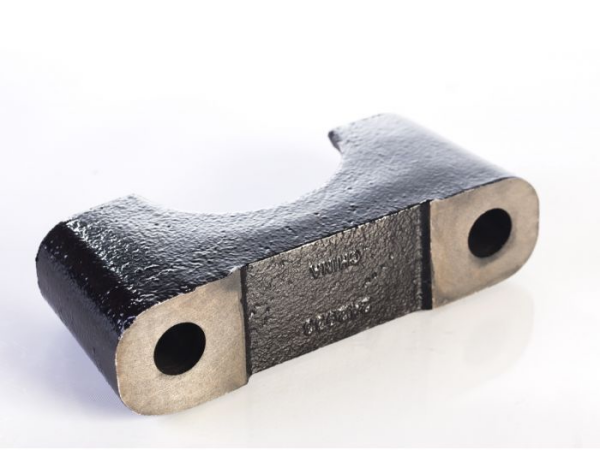

Casting: the method of melting metal, making mold, pouring molten metal into the mold, and obtaining the blank of metal parts with certain shape, size and performance after solidification.

Casting is the process of melting metal into a liquid that meets certain requirements and pouring it into the mold. After cooling, solidification and cleaning, the casting with predetermined shape, size and performance can be obtained. Because the casting blank is nearly formed, it can achieve the purpose of no mechanical processing or less processing, which reduces the cost and reduces the production time to a certain extent. Casting is one of the basic processes of modern device manufacturing industry.

Casting is a metal hot working process that human beings have mastered relatively early, and has a history of about 6000 years. China has entered the heyday of bronze casting between 1700 and 1000 BC, and its technology has reached a very high level.

Casting is the method of casting liquid metal into the casting cavity corresponding to the shape of the part, and obtaining the part or blank after its cooling and solidification.

The materials to be cast are mostly metals (such as copper, iron, aluminum, tin, lead, etc.) that are originally solid but heated to liquid state. The materials for ordinary casting are raw sand, clay, water glass, resin and other auxiliary materials. The mold of special casting includes investment casting, lost foam casting, metal mold casting, ceramic mold casting, etc. (Raw sand includes quartz sand, magnesia, zirconium sand, ferrochrome sand, forsterite sand, kyanite sand, graphite sand, iron sand, etc.)

Advantages:

1. It can produce parts with complex shapes, especially blanks with complex cavities;

2. Wide adaptability, metal materials commonly used in industry can be cast, from a few grams to hundreds of tons;

3. The source of raw materials is wide and the price is low, such as scrap steel, scrap parts, chips, etc;

4. The shape and size of the casting are very close to the parts, which reduces the cutting amount and belongs to non-cutting processing;

5. It is widely used. 40%~70% of agricultural machinery and 70%~80% of machine tools are castings.

Disadvantages:

1. Mechanical properties are inferior to forgings, such as coarse structure and many defects;

2. In sand casting, single piece and small batch production make workers labor intensive;

3. The casting quality is unstable, there are many processes, the influencing factors are complex, and many defects are easy to occur.