Factors Affecting the Quality of Iron Castings

Factors Affecting the Quality of Iron Castings

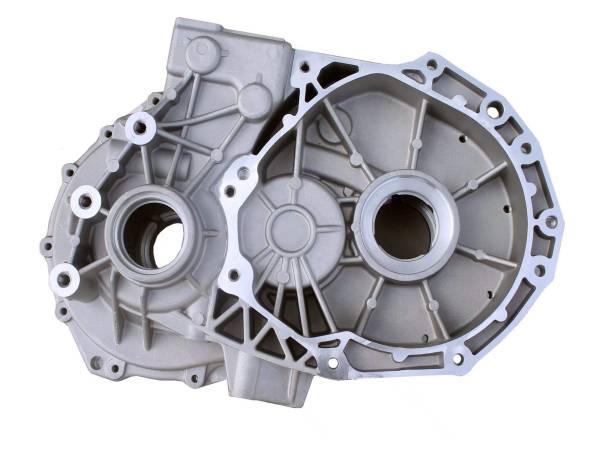

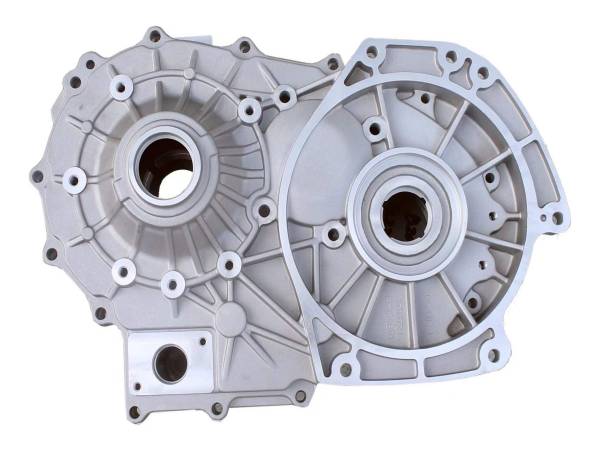

First, the design process of iron castings. During the design, in addition to determining the geometric shape and size of the cast iron according to the working conditions and metal material properties, the rationality of the design must also be considered from the perspective of casting alloy and casting process characteristics, that is, obvious size effect and solidification, shrinkage, stress and other problems, in order to avoid or reduce the occurrence of component segregation, deformation, cracking and other defects of the cast iron.

Second, there should be a reasonable casting process. That is, according to the structure, weight and size of iron castings, casting alloy characteristics and production conditions, select the appropriate parting surface and modeling, core making method, and reasonably set the casting rib, chill, riser and gating system. To ensure the availability of iron castings.

Third, the quality of raw materials for casting. The substandard quality of metal charge, refractory material, fuel, flux, modifier, casting sand, molding sand binder, coating and other materials will cause defects such as air holes, pinholes, slag inclusion, sand sticking and other defects in the cast iron, affecting the appearance quality and internal quality of the cast iron, and in serious cases, the cast iron will be scrapped.

The fourth is process operation. It is necessary to formulate reasonable process operation procedures, improve the technical level of workers, and ensure the correct implementation of process procedures.

During manufacturing, the quality of castings should be controlled and inspected. First of all, we should formulate the process rules and technical conditions for the control and inspection of each specific product from raw materials and auxiliary materials. Each process shall be controlled and inspected in strict accordance with the process rules and technical conditions. Conduct quality inspection on finished castings. Reasonable testing methods and appropriate testing personnel shall be equipped. Generally, for the appearance quality of professional iron castings, the surface roughness of castings can be judged by comparing sample blocks; Tiny cracks on the surface can be inspected by coloring method and magnetic particle method.