How about the properties of cast iron castings

Cast iron includes grey cast iron, nodular cast iron, vermicular cast iron, white cast iron and various alloy cast iron; According to machinability, gray cast iron, pearlitic ductile iron and some alloy cast iron are easy to cut; Vermicular cast iron, white cast iron and high alloy wear-resistant cast iron (SUCH high nickel chromium alloy cast iron, hardness HRC60) are hard cutting materials. The impact properties of iron castings will be discussed below.

Impact performance refers to the performance and ability of materials to resist fracture under the impact force. This ability is measured by the energy absorbed by the material during fracture. Impact test is usually used to measure impact absorbed energy. The impact absorption energy is expressed by the power consumed per unit section area or the total energy absorbed when the sample breaks. It includes elastic work, plastic work and fracture work during crack propagation.

The results of impact test can not accurately reflect the fracture work of materials. Fracture work is a real index reflecting the impact toughness of materials. Therefore, the impact absorbed energy is generally not used in the strength design of products, but only used to compare the brittleness or ductility brittleness transition temperature of materials, or as a performance index of materials that fail after being impacted by large energy.

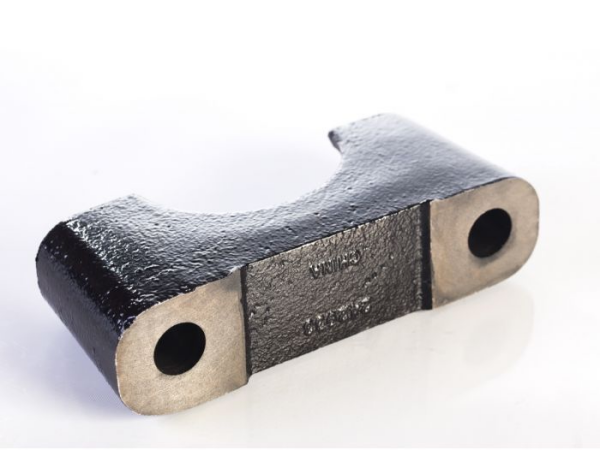

Cast iron is obtained through spheroidizing and incubation treatment, which effectively improves the mechanical properties of cast iron, especially plasticity and toughness, so as to obtain higher strength than carbon steel. The comprehensive properties of iron castings are close to that of steel, and they have been successfully used to forge some parts with complex stress, high requirements for strength, toughness and wear resistance. Today, we will discuss the classification of cast iron parts.

Attention must be paid to safety during the construction of iron castings to prevent personal injury to operators. What are the main safety precautions during the construction of iron castings? Attention shall be paid to the construction of iron castings. When drilling holes on the floor, hold the chisel tightly and use a hand hammer or electric hammer to drill holes. The hole shall be drilled gradually, and the eye shall not be hit with a sledgehammer. Cast iron casting holes shall not be detained to avoid hitting.

During the construction of iron castings, attention shall be paid to the construction climbing operation, and manned ladders and stools shall be used for monitoring, and safety helmets shall be worn. During the construction of iron castings, it shall be noted that objects shall not be thrown up or down, but only hung up with ropes. When using electric equipment, operators shall master the performance of various machines and tools and pay attention to the safety of electrical equipment. Electric welding tools, water welding tools, manual tungsten and argon arc welding machines shall pay attention to the construction of iron castings, strictly observe the safety protection measures and improve the safety protection equipment.