How To Make Gearbox Housing Wear Resistant?

Among various mechanical equipment, the engine and gearbox can be said to be a combination of "heart + center". And their shells - that is, the part that bears strong power and resists high temperature and high pressure - are often produced in the sand casting way. Why choose sand casting? Because it is stable, strong and precise enough!

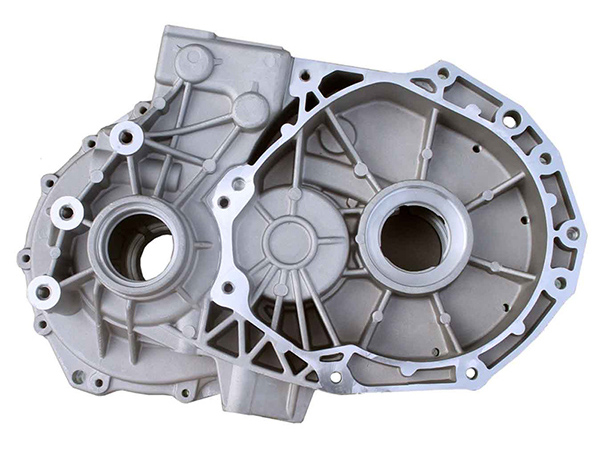

The castings used for iron sand casting gearbox have high requirements, not only complex structure, but also sufficient mechanical strength and wear resistance, and must meet the dual standards of dimensional accuracy and surface quality. This type of sand casting we produce is tailored for the power system and can adapt to various types of engines and gearbox housing ductile iron sand casting needs, whether it is passenger cars, construction machinery, agricultural equipment, or industrial power units.

Our gearbox housing ductile iron sand casting is rich in variety, from gearbox housings, clutch housings, cylinder blocks, cylinder heads, to various transmission component housings, all of which can be customized according to customer drawings. Gearbox housing ductile iron sand casting uses high-quality pig iron or alloy steel materials, combined with advanced resin sand and clay sand casting processes to ensure that each product has high strength, high temperature resistance, and is not easy to deform.

We know that every customer has different performance requirements for gearbox housing ductile iron sand casting. In order to meet the diverse customization needs, we have built a flexible and efficient production system. From the early drawing review and model development, to the mid-term sample verification and batch casting, to the later iron sand casting gearbox machining and quality inspection packaging, every link is meticulous and in place, without missing any details.

Speaking of our production capacity, this is part of our pride. Fuding is equipped with a number of advanced resin sand molding lines and clay sand automatic molding lines, which can meet the needs of castings of different materials and sizes.

And in terms of testing, we are not ambiguous at all. The Fuding factory is equipped with a series of testing equipment such as spectrometer, three-coordinate measuring instrument, ultrasonic flaw detector, hardness tester, metallographic microscope, etc., to ensure that every sand casting shipped out of the factory is "healthy". If you have special requirements for iron sand casting gearbox quality, such as testing after machining, we can also provide complete processing + quality inspection integrated services.

In addition to iron sand casting gearbox products, we also produce various sand casting mechanical structural parts, pump body valve body, wheel hub, machine tool basic components and other sand castings for a long time, serving many industries such as automobiles, ships, mining, wind power, hydraulics, and agriculture. Whether it is small batch customization or large batch delivery, we can cooperate flexibly.

We believe that a good sand casting is not only "cast", but also "communicated" and "understood". Every time we cooperate, we listen carefully to the needs of customers and provide customers with the most suitable material selection, structural suggestions and processing methods. If you are looking for a reliable casting partner for iron sand casting gearbox, please contact us, maybe we are the one you are looking for.

If you have the opportunity, please come to visit the factory, take a look at the steaming sand casting workshop, listen to the rhythm of the equipment operation, and feel the charm of manufacturing. Maybe you will find that a seemingly inconspicuous sand casting actually hides a lot of technology and wisdom.