Material Selection For Automotive Manifolds

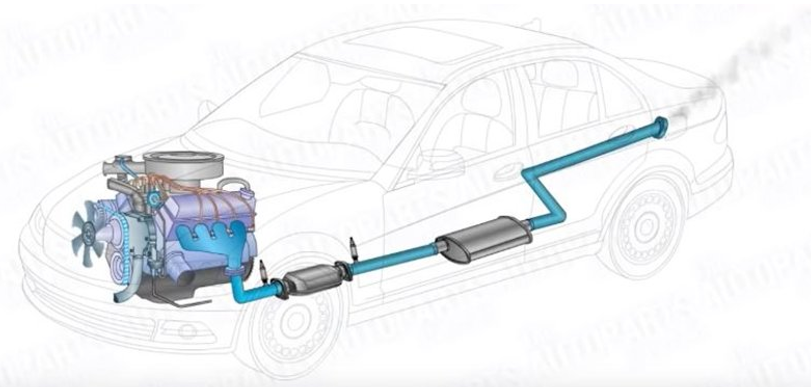

Under the hood of every car is a complex structure called the automobile exhaust manifold , which is connected directly to the car's engine through several tubes. In addition to playing a key role in removing exhaust gases, manifolds also optimize a car's efficiency and performance.

Difference between intake and exhaust manifolds?

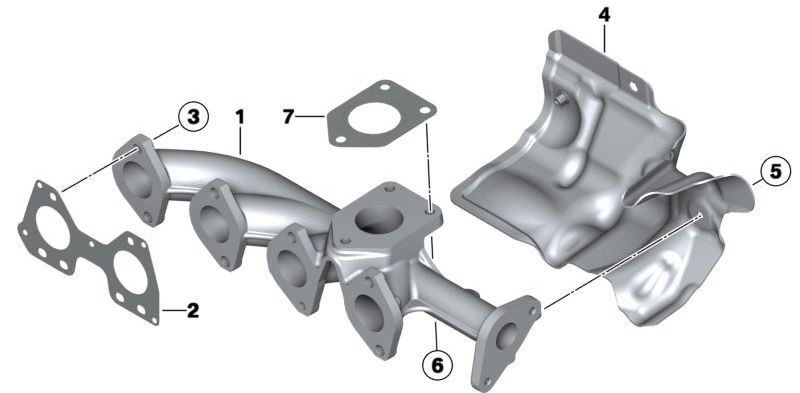

The intake manifold is responsible for distributing the fuel-air mixture into the internal cylinders for combustion, while the exhaust manifold carries away gases, the byproducts of combustion. Therefore, it is important not to get each component wrong.

In addition to serving as a channel and pathway for exhaust gases to pass from the combustion chamber into the exhaust pipe, the exhaust manifold also helps improve the fuel efficiency of the engine output and enhances the overall performance of the car.

What is Excavator exhaust manifold?

The automobile exhaust manifold is an integral part of the engine system and plays a vital role in ensuring that the engine operates efficiently. Its main function is to collect the burned exhaust gas in the engine cylinder and guide it to the exhaust pipe. The system consists of pipes and ducts that connect the internal combustion chamber to the exhaust system.

Many people often refer to the automobile exhaust manifold simply as a manifold. However, we must tell you that a typical automotive system consists of an intake manifold and an exhaust manifold.

Different Materials for Manufacturing Excavator exhaust manifold:

Cast iron

Cast iron is one of the most commonly used materials for manufacturing Excavator exhaust manifolds. Cast iron is widely used due to its ability to withstand harsh conditions such as high temperatures and corrosion and therefore has a long service life.

However, the main disadvantage of cast iron is weight; it is heavy, especially compared to other materials like aluminum. The high density also makes customizing Excavator exhaust manifolds using this material challenging. However, due to its cost-effectiveness, it remains the material of choice for large-scale manufacturing of passenger car exhaust systems.

Aluminum

Aluminum is the material of choice for automobile exhaust manifold. Its unique properties, such as incredible strength-to-weight ratio and corrosion resistance, have greatly benefited the automotive industry. Its low density makes it a key material for reducing the weight of cars, for example.

Aluminum is less durable than other materials like steel. However, the automotive industry places emphasis on weight reduction, which is critical to optimizing engine performance and achieving higher torque and speed in racing cars. Additionally, aluminum is an excellent conductor of heat.

Stainless steel

Stainless steel is also one of the most commonly used automobile exhaust manifolds. It has excellent properties compared to many materials, including considerable strength, ease of molding, corrosion resistance, corrosion resistance, and durability.

However, it is relatively more expensive but still offers the right balance between cost and performance. Like aluminum, stainless steel is easy to machine and work with, making it a practical choice for custom exhaust manifold fabrication. Additionally, it is a very durable material, ensuring that it creates a long-lasting automobile exhaust manifold.

Our company is a manufacturer specializing in mechanical parts processing, producing a variety of Excavator exhaust manifold that meet your requirements. We have a professional quality supervision department, and every automobile exhaust manifold produced has undergone strict quality testing and has a long service life. We can provide customized services, whether it is size or material, to meet your needs.