What are the main steps of sand casting process

For foundries, sand casting process is a relatively complex process with many combined processes. So, what are the main processes involved in sand casting technology? Today, let's give you a detailed introduction.

1. Before starting casting, we need to create a process diagram based on the casting drawings to determine the casting process. By using some software to determine whether the sand casting process is feasible, standard wooden models can be made if possible.

2. Work before starting formal production: Prepare materials for molding and core making, sand boxes, production materials, and core boxes, etc.

3. Next is the sand mixing process. We need to adjust the sand mold according to the requirements of sand casting and different casting types, and the adjusted sand mold can be used for molding.

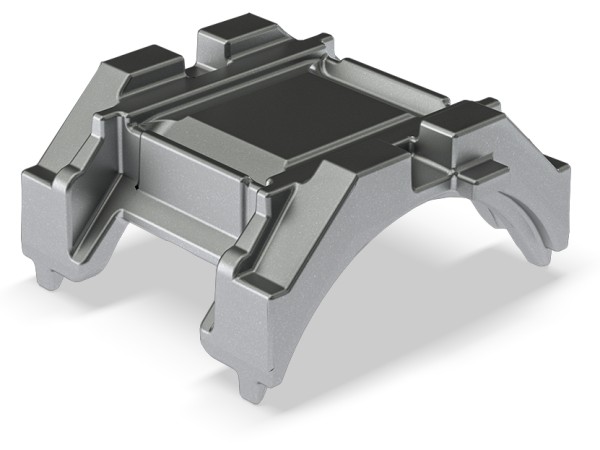

4. The next step is to make cores, shape and match molds. Core making is the shape inside the casting; The molding is a casting cavity cast with sand mold, followed by placing clay cores inside the cavity, and then placing the upper and lower sand boxes together to complete the mold matching. Modeling is a crucial step in the sand casting process.

5. The casting factory will match the chemical composition according to the required composition, and choose a better melting material in order to obtain a qualified molten steel.

6. Pour the processed molten steel liquid into the previously prepared sand box, and then proceed with pouring.

7. After completing the pouring, wait until the metal liquid has completely solidified, and then clean the excess sand particles and falling sand, remove the gate and other accessories, and a finished casting is completed.

8. The final step of sand casting process is testing, and we can use machines to conduct testing to see if it meets the requirements.

The above is an introduction to the entire process of sand casting. Although each step may not seem so complex, it is still quite troublesome to truly do it. The key is to ensure that every step in these processes can be successfully completed to avoid defects in the casting, which can affect the quality of the product.