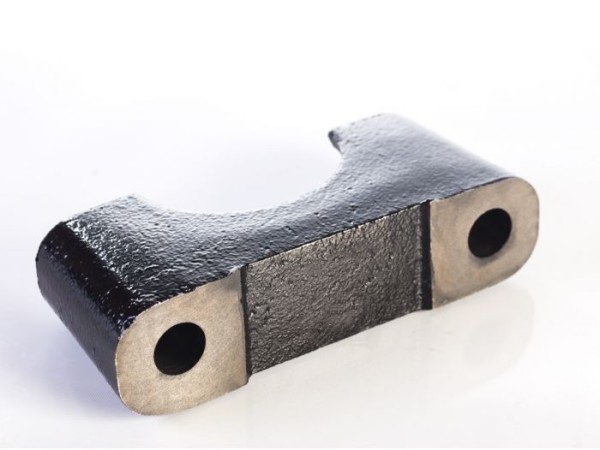

What are the rust prevention measures for cast iron parts

Cast iron is a commonly used industrial material with good mechanical and wear resistance, but it is also susceptible to oxidation and corrosion. Therefore, during production and use, it is necessary to take some rust prevention measures to protect the surface of cast iron castings and extend their service life.

Coating rust prevention is a common method of rust prevention, usually using coatings or coatings to cover the surface of cast iron parts and prevent them from being exposed to air and water. Common coating materials include paint, epoxy resin, polyurethane, etc. The advantages of coating rust prevention are low cost and easy construction, but the disadvantage is poor durability and the need for regular maintenance.

Chemical rust prevention is the use of chemicals to prevent oxidation and corrosion on the surface of iron castings. Commonly used chemical substances include acid washing agents, alkali washing agents, phosphating agents, etc. These chemicals can react with oxides or dirt on the surface of cast iron, forming a protective film to prevent further oxidation and corrosion of the cast iron. The advantage of chemical rust prevention is its good rust prevention effect, but it is necessary to pay attention to the selection and use of chemical substances to avoid harm to the environment and human body.

3. Electrochemical rust prevention

Electrochemical rust prevention is the process of using cast iron as an anode and forming a battery with cathode materials (such as zinc, aluminum, etc.) to prevent oxidation and corrosion on the surface of cast iron through current. This method requires the use of external power sources, requires high investment and technical support, but can protect the surface of cast iron from oxidation and corrosion for a long time.

Alloying rust prevention is the use of adding a certain proportion of alloy elements (such as chromium, molybdenum, cobalt, etc.) to cast iron to enhance its oxidation and corrosion resistance. This method can be carried out during the production process without the need for additional investment and human resources, but it requires the selection of alloy elements and control of the addition ratio based on specific circumstances.