What is the difference between ductile iron and cast iron

Ductile iron and cast iron are two different types of alloys, and their characteristics, structure, and performance are also different. Below, we will explore the differences between ductile iron and cast iron from the perspectives of material composition, physical properties, and mechanical properties.

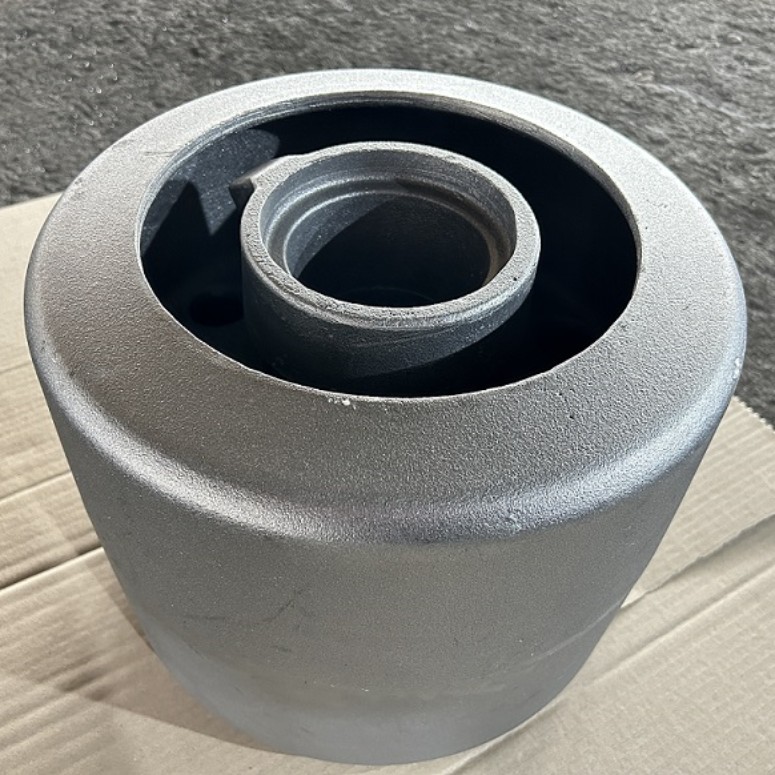

The material composition of ductile iron and cast iron is different. Cast iron is an iron-carbon alloy that contains a large amount of carbon, with a carbon content generally ranging from 2.1% to 4.5%. Ductile iron, on the other hand, adds a certain amount of magnesium and rare earth elements to the cast iron, and through spheroidization treatment, the graphite in the molten iron becomes spherical, thereby increasing the toughness and strength of the alloy.

The physical properties of ductile iron and cast iron are also different. Cast iron has good wear resistance and hardness due to its high content of carbon, but it is also very brittle. The spherical graphite of nodular cast iron can effectively hinder crack propagation, thereby enabling the alloy to have better toughness and impact resistance. In addition, the coefficient of thermal expansion and thermal conductivity of nodular cast iron are also lower than that of cast iron, so it can maintain stability under high temperature and high pressure.

The mechanical properties of ductile iron and cast iron are also different. Cast iron has high hardness and wear resistance due to its high carbon content, but it is also brittle and prone to fracture. Due to the graphite morphology treated with spheroidization, ductile iron can effectively prevent crack propagation, thus possessing better toughness and ductility, and can withstand larger loads and impacts. In addition, the strength and hardness of ductile iron are also higher than that of cast iron.

The difference between ductile iron and cast iron mainly lies in material composition, physical properties, and mechanical properties. Although cast iron has high hardness and wear resistance, it is also very brittle, while ductile iron increases the toughness and strength of the alloy through spheroidized graphite morphology, which can withstand greater loads and impacts. In practical applications, we need to choose appropriate materials based on specific engineering needs.