Which is stronger, steel castings or cast iron castings

Which is better, steel castings or cast iron castings? Let's explore today!

(1) Different properties

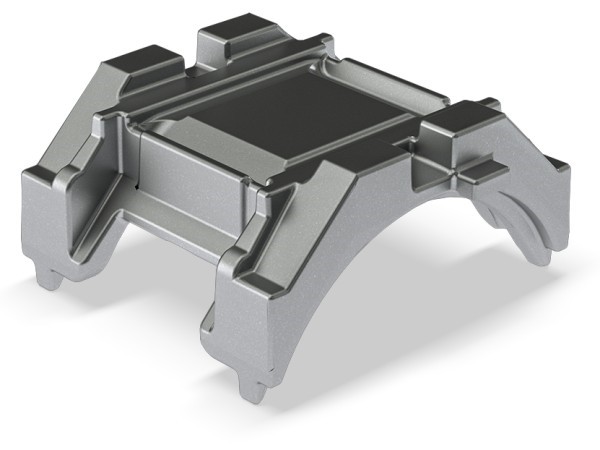

Steel castings are made from steel specifically used for manufacturing steel castings.

Iron castings are mainly cast from alloys composed of iron, carbon, and silicon.

(2) Different uses

1. Steel castings can be divided into cast alloy steel and cast carbon steel based on their chemical composition, as well as into cast tool steel, cast special steel, engineering and structural casting, and cast alloy steel based on their usage characteristics.

2. Cast iron parts are suitable for mass production of thin-walled parts due to their longer annealing time, complex production process, and high production cost.

(3) Different characteristics

Compared to iron castings, steel castings have the following characteristics:

1. Strong plasticity. Manufacturers can freely design the shape and size of castings. Especially for parts with complex shapes, steel castings can be easily held and pinched.

2. The design speed is fast, and due to its flexibility in changing shape, manufacturers can greatly shorten the time from design drawings to finished products, greatly saving delivery time.

3. The weight of steel castings is not fixed, and you can choose to increase or decrease them. Whether you need dozens of grams of precision castings or hundreds of tons of large castings, steel castings can be easily processed.

4. The overall structure of steel castings is very strong, and it is self-evident to choose them for reliable engineering assurance.

Iron castings are also not inferior, as they can absorb vibration waves, prevent or reduce mechanical vibration damage to components, and also have the ability to absorb noise. Its wear resistance and maneuverability are also excellent!

Steel castings and cast iron castings each have their own advantages, and can be selected based on their own requirements for casting performance.