Automotive Suspension Control Arm

Brand Dandong Fuding Engineering Machinery Co.,Ltd.

Product origin Liaoning Dandong

Delivery time 1month after receiving the order

Supply capacity 2000 tons per month

1. The Automotive Suspension Control Arm uses a high-precision manufacturing process to enable the control arm to provide stable performance during use.

2. The Automotive Suspension Control Arm can withstand long-term wear and impact and maintain stable performance.

3. The Automotive Suspension Control Arm has precise dimensions and design to fit a variety of vehicle models.

Product introduction of suspension control arm:

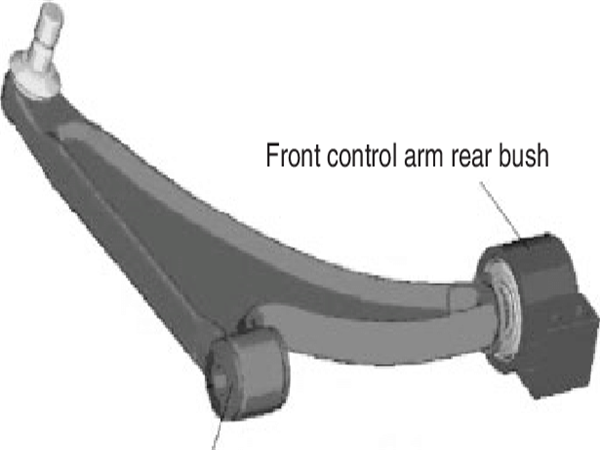

The control arms are one of the core components of a suspension system and serve as the direct connection points between the front wheel assemblies and the vehicle's frame. Although they are simplistic in appearance, control arms have a vital role in a vehicle's overall stability and drivability. Found on virtually all road-going suspension systems, control arms are located at the front axle at each of the two front wheels. Suspension control arms made by us are comprised of cast iron as their primary material. Cast iron control arms deliver strength, sturdiness, and the ability to resist damage.

Product advantages of suspension control arm:

1. The iron cast control arm produced by our company adopts advanced casting, forging and machining processes to ensure the dimensional accuracy and surface quality of each control arm. Our company has a professional quality supervision department that conducts strict testing on every iron cast control arm produced.

2. The iron cast control arm produced by our company has precise size and design, which makes the installation and replacement of our iron cast control arm easier, with high repair efficiency and low maintenance cost.

3. We can provide customized iron cast control arm according to the special needs of customers to meet the requirements of different models and usage environments.

Production steps:

Step1: Drawing and technical requirement analysis, production lofting;

Step2: Material cutting, trimming, groove, cleaning, bending, rolling, dimension & NDT inspection

Step3: From part assemble to whole assemble with accurate template and platform, dimension & NDT inspection, welding, dimension & NDT inspection;

Step4: Casting, forging, stamping, machining if necessary

Step5: Final dimension & NDT inspection;

Step6: Surface treatment;

Step7: Package, Loading and Lashing when delivery;

About us:

Dandong Fuding Engineering Machinery Co., Ltd. was founded in 1958. Our company is a factory specializing in the production of automotive casting parts and has more than 60 years of production and processing experience. A variety of iron cast control arm can be produced to meet your requirements. Our company has a professional after-sales department that can provide you with timely and effective after-sales service. We are well-known in the industry and our products are sold overseas. We look forward to long-term and close cooperation with you.