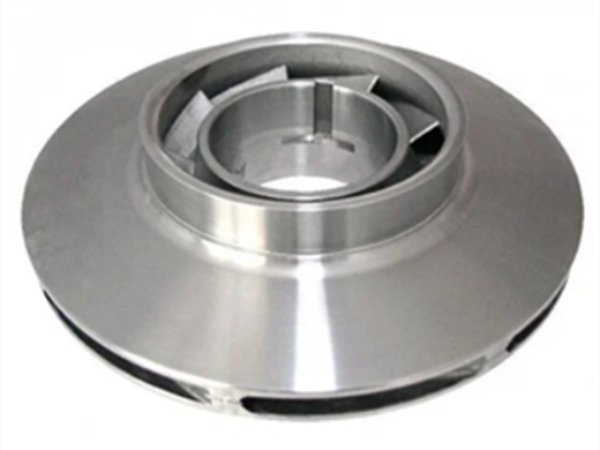

Forklift Bearing Cap

Brand Dandong Fuding Engineering Machinery Co.,Ltd.

Product origin Liaoning Dandong

Delivery time 1 month after receiving the order

Supply capacity 2000 tons per month

1. Casting bearing cap can prevent dust and pollution.

2. Casting bearing cap is light in weight and high in strength.

3. Casting bearing cap is made of high-quality materials and has a long service life.

Product introduction of casting bearing cap:

The casting bearing cap of a forklift is a key component of the forklift engine. It is usually a cap-like part made of iron or aluminum alloy and is located at the bottom of the engine crankcase. The main function of the crankshaft bearing cap is to fix and support the main bearing on the engine crankshaft, and to fasten it to the crankcase through bolts. Different models of forklifts generally require different types of casting bearing cap accessories. Our company can provide a variety of sizes and models of casting bearing cap accessories for you to choose.

Product advantages of main bearing cap:

1. The main bearing cap produced by our company is made of high-quality raw materials and can be used for a long time under various environmental conditions. Our company has a professional quality supervision department that conducts strict testing on every crankshaft bearing cap produced.

2. Our company has a professional R&D team. The crankshaft bearing cap produced can be compatible with various forklift brands and models, and can be customized and designed according to customer needs to ensure a perfect fit between the product and customer equipment.

3. Purchasing the crankshaft bearing cap produced by our company means choosing an experienced and reputable manufacturer, and your purchase will be guaranteed.

Need to know when using main bearing cap:

1. Make sure the main bearing cap is installed correctly according to the installation instructions provided by the manufacturer. Proper installation ensures its performance and stability.

2. Regularly check the worn parts of the crankshaft bearing cap and replace them in time as needed to ensure the normal operation of the product.

3. Follow the use and maintenance recommendations provided by the manufacturer to ensure the safety and performance of the crankshaft bearing cap.

More details of main bearing cap:

Size and Design of main bearing cap:

* As per the customer's drawings and requirements;

* As per the customer's samples;

Packing of main bearing cap:

* Wooden cases;

* Steel cases;

* Cartons;

* As per customers' requirements;

Inspection of main bearing cap:

* Foundry in-house;

* Third Party inspection available upon customers requirements;

About us:

Dandong Fuding Engineering Machinery Co.,Ltd., was founded in 1958. Our company is a factory specializing in the production of industrial casting parts and can produce a variety of main bearing caps that meet your requirements. Our company has a professional team and a complete after-sales service system to provide customers with all-round support and services. Whether it is product consultation, installation guidance or after-sales maintenance, we will be happy to help you.